Validation Process for Heat Treating Equipment

Click to download full version of Requirement Flowdown.

As I’m sure many of you are aware flow-down issues can introduce significant challenges to sub-tier suppliers, causing unnecessary delays during the resolution process and introducing the potential for nonconformities. Information received by a sub-tier can often be confusing, contradictory or incomplete. However, initial purchase order review and acceptance is a critical process step for Applied Thermal Technologies, in which we both determine if our organization has the ability to meet the defined requirements and create a job traveler defining the procedures necessary to do so. Because numerous requirements contained in various documents such as drawings, process specifications, and material specifications often exist, an established hierarchy of requirements exists to manage these sometimes divergent documents.

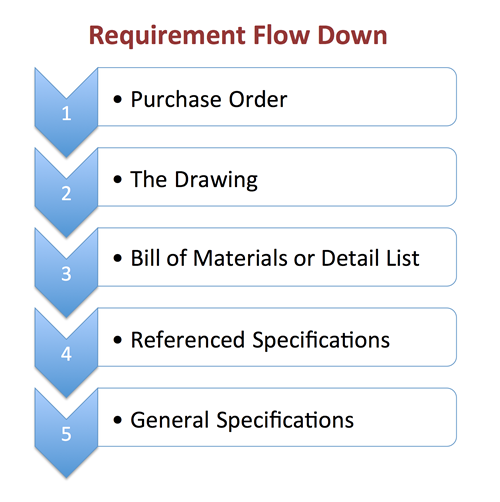

The order of precedence is as follows:

- Purchase Order

- The Drawing

- Bill of Materials or Detail List

- Referenced Specifications

- General Specifications.

(Where a customer specific specification conflicts with a specification SAE AMS, MIL or ASTM standard, the customer specific document will take precedence).

It is the policy and practice of Applied Thermal Technologies to attempt to resolve any flow-down discrepancies in writing prior to order acceptance and processing, however, please keep in mind that the purchase order will ultimately override all other requirements. Click here to see more details.