Vacuum Brazing Service

Brazing is somewhat similar to welding and it is just one of the many heat services that Applied Thermal Technologies, Inc. is capable of handling. Brazing is a versatile process that is used on a large number of metal alloys. Our brazing services include vacuum or hydrogen atmosphere, assembly, braze repair, hydrogen fluoride cleaning hard surfacing, and ceramics with or without metallizing. If you have questions, you may fill in the contact information on our website and we will get back to you ASAP. We also have the equipment to do annealing, tempering and hardening.

Brazing of Titanium

Brazing of stainless steel & carbon steel components. Utilize copper, silver, nickel & low temperature brazing alloys. Assembly, testing & annealing services. (Nadcap Certified).

Brazing of Stainless Steel

Brazing of stainless steel & carbon steel components. Utilize copper, silver, nickel & low temperature brazing alloys. Assembly, testing & annealing services. (Nadcap Certified).

Vacuum Furnace Brazing

Applied Thermal Technologies Inc. was created in 1992 to service the medical and specialty products industries of Northern Indiana, specializing in bright vacuum heat treating and furnace brazing of stainless steel and exotic metal alloys. We work closely with each customer in determining their particular engineering requirements and are available for technical assistance in metallurgy, heat treating, and furnace brazing. Our furnace brazing services include vacuum or hydrogen atmosphere, assembly, braze repair, hydrogen fluoride cleaning, hard surfacing, ceramic brazing with or without metallizing. Visit our website for more information.

What does Vacuum Brazing stand for? Definitions ...

What does Brazing stand for? Definitions ...

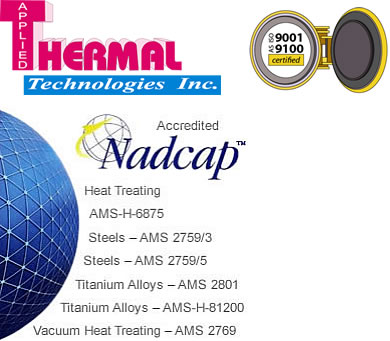

Our NadCap Certified processes

Applied Thermal Technologies can comply with the following industry standards and specifications:

AMS 2675, Nickel Alloy Brazing, AMS 2750, Pyrometry, AMS 2759, Heat Treatment of Steel Parts–General Requirements, AMS 2759/3, Heat Treatment–P.H. , C.R. , and Maraging Steel Parts, AMS 2759/4, Heat Treatment–Austenitic Corrosion Resistant Steel Parts, AMS 2759/5, Heat Treatment–Martensitic Corrosion Resistant Steel Parts, AMS 2769, Heat Treatment of Parts in Vacuum,AMS 2773, Heat Treatment–Cast Nickel Alloy and Cobalt Alloy Parts,AMS 2774, Heat Treatment–Wrought Nickel Alloy and Cobalt Alloy Parts,AMS 2801, Heat Treatment of Titanium Alloy Parts, MIL-B-7883, MIL-H-6875, MIL-H-81200

For the aerospace and medical device industries; sintering and ceramic bright annealing are done using our industrial furnaces feature temperatures to 2800°F, levels to 10-6 Torr, all metal hot zones and cooling. Several brazing techniques are applicable to titanium, stainless steel and carbon steel components where we utilize nickel and low temperature brazing alloys. Our personnel work closely with you to determine your particular requirements for heat treating or sintering your titanium, nickel, ceramic and bright annealing parts.